Application of PAM in water treatment industry mainly includes three aspects: raw water treatment, sewage treatment and industrial water treatment. In raw water treatment, PAM and activated carbon used together, can be used for coagulation and clarification of suspended particles in living water; In sewage treatment. PAM can be used for sludge dewatering; In industrial water treatment, PAM is mainly used as a formulation agent. In raw water treatment, using organic flocculant PAM instead of inorganic flocculant, the water purification capacity can be increased by more than 20% even without reforming sedimentation tank. So at present, many large and medium-sized cities in the water supply shortage or poor water quality, are using PAM as a supplement. Industrial wastewater treatment, especially for suspended particles, coarse, high concentration, particles with positive charge, PH value of water neutral or alkaline sewage, iron and steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other sewage treatment, the best effect. In wastewater treatment, PAM can increase the utilization rate of water reuse cycle.

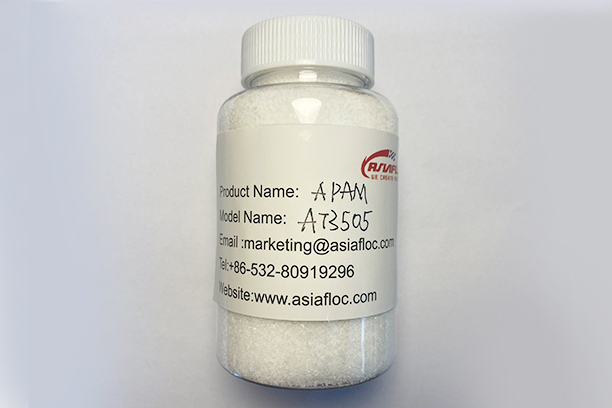

Anionic polyacrylamide Water treatment anionic polyacrylamide manufacturer|

Anionic polyacrylamide|anionic polyacrylamide suppliers|anionic polyacrylamide manufacturer|

Water treatment.

Application of PAM in water treatment industry mainly includes three aspects: raw water treatment, sewage treatment and industrial water treatment. In raw water treatment, PAM and activated carbon used together, can be used for coagulation and clarification of suspended particles in living water; In sewage treatment. PAM can be used for sludge dewatering; In industrial water treatment, PAM is mainly used as a formulation agent. In raw water treatment, using organic flocculant PAM instead of inorganic flocculant, the water purification capacity can be increased by more than 20% even without reforming sedimentation tank. So at present, many large and medium-sized cities in the water supply shortage or poor water quality, are using PAM as a supplement. Industrial wastewater treatment, especially for suspended particles, coarse, high concentration, particles with positive charge, PH value of water neutral or alkaline sewage, iron and steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other sewage treatment, the best effect. In wastewater treatment, PAM can increase the utilization rate of water reuse cycle.

Oil production.

In petroleum exploitation, PAM is mainly used in drilling mud materials and improve oil recovery rate and other aspects, widely used in drilling, completion, cementing, fracturing, enhanced oil recovery and other oilfield exploitation operations, with viscosity, filtration, rheological regulation, gelling, shunt, profile adjustment and other functions. At present, China's oilfield exploitation has entered the middle and late stage. In order to improve oil recovery, polymer flooding and asp flooding technology are mainly promoted at present. By injecting PAM solution, the oil-water velocity ratio was improved and the content of crude oil in the produced product was increased. At present, PAM is not widely used in oilfields abroad. Due to special geological conditions, Polymer flooding technology has been widely used in Daqing oilfield and Shengli oilfield in China.

Paper industry.

PAM is widely used as a resident agent, filter aid and homogenizer in the field of paper making. Its function is to improve the quality of paper, improve the dehydration performance of slurry, improve the retention rate of fine fiber and filler, reduce the consumption of raw materials and environmental pollution. The effectiveness of PAM in papermaking depends on its average molecular weight, ionic properties, ionic strength and the activity of other copolymers. Non-ionic PAM is mainly used to improve the filter properties of pulp, increase the strength of dry paper, improve the retention rate of fiber and filler; Anionic copolymer is mainly used as dry and wet intensifier and resident agent of paper; Cationic copolymer is mainly used in papermaking wastewater treatment and filtration aid, and also has good effect on improving the retention rate of fillers. In addition, PAM is also used in papermaking wastewater treatment and fiber recovery.

Textile field.

In the textile industry, PAM as fabric post-treatment sizing agent, finishing agent, can generate a soft, wrinkle resistant, mold resistant protective layer. The yarn breaking rate can be reduced by using its high moisture absorption. PAM as post-treatment agent can prevent static electricity and flame retardant fabric; PAM can make the product adhere to the fastness, high brightness, can also be used as a bleaching non-silicon polymer stabilizer; In addition, PAM can also be used for efficient purification of textile dyeing wastewater.

Other fields in mining, coal washing, the use of PAM as flocculant can promote mining, coal washing recovery of solid water settlement, water clarification, at the same time can recover useful solid particles, to avoid environmental pollution; In sugar industry, PAM can accelerate the sinking of fine particles in sugarcane juice, promote filtration and improve the clarity of filtrate. In the aquaculture industry, PAM can improve water quality, increase the light transmittance of water, thereby improving the photosynthesis of water; In the pharmaceutical industry, PAM can be used as a flocculant for the separation of antibiotics, as a binder for tablets and process water clarification agent, etc. In the building materials industry, PAM can be used as coating thickening dispersant, saw stone plate coolant and ceramic adhesive; In agriculture, PAM as a highly absorbent material can be used as soil humectant and seed culture agent. In the construction industry, PAM can enhance the hardness of gypsum cement and speed up the dehydration of asbestos cement. In addition, PAM can also be used as protective coating for natural or synthetic leather and granulation agent for inorganic fertilizer.

The quantity of anionic polyacrylamide in coal washing tank is a very particular subject. If the amount is too large, it will cause a waste, if the amount is not enough, it is difficult to product effect, therefore, anionic polyacrylamide manufacturer Taiyu company suggests here, the correct and reasonable use should be 1/1000 of the proportion, that is, a jin of amide, can use 1000 jin of water. According to this index, under normal circumstances, the coal and water can be successfully separated within a certain period of time. After separation, the water on the surface will be put out, and then the slime at the bottom of the pool will be left. After drying and drying, it can be used as normal coal.

551.jpg)