Water treatment includes raw water treatment, sewage treatment and industrial water treatment. In raw water treatment with activated carbon, etc., can be used for coagulation and clarification of suspended particles in living water. If organic flocculant acrylamide is used instead of inorganic flocculant, the water purification capacity can be increased by more than 20% even without reforming sedimentation tank. In sewage treatment, the use of polyacrylamide can increase the utilization rate of water recycling cycle, but also can be used for sludge dewatering; It is used as an important ingredient in industrial water treatment. Polyacrylamide in the biggest field of foreign application is water treatment, domestic application in this field is being promoted.

Application of anionic polyacrylamide Magnafloc 345,351,355

Application of anionic polyacrylamide Magnafloc 345,351,355

1. Water treatment

Water treatment includes raw water treatment, sewage treatment and industrial water treatment. In raw water treatment with activated carbon, etc., can be used for coagulation and clarification of suspended particles in living water. If organic flocculant acrylamide is used instead of inorganic flocculant, the water purification capacity can be increased by more than 20% even without reforming sedimentation tank. In sewage treatment, the use of polyacrylamide can increase the utilization rate of water recycling cycle, but also can be used for sludge dewatering; It is used as an important ingredient in industrial water treatment. Polyacrylamide in the biggest field of foreign application is water treatment, domestic application in this field is being promoted.

The main role of polyacrylamide in water treatment:

(1) Reduce the dosage of flocculant. Under the premise of achieving the same water quality, polyacrylamide as coagulant aid and other flocculants used together, can greatly reduce the amount of flocculant use; Under the premise of achieving the same water quality, polyacrylamide as coagulant aid and other flocculants used together, can greatly reduce the amount of flocculant use;

(2) Improve water quality. In the treatment of drinking water and industrial wastewater, polyacrylamide and inorganic flocculant can obviously improve the water quality.

(3) Improve the floc strength and sedimentation velocity. The flocculant formed by polyacrylamide has high strength and good settling performance, which improves the solid-liquid separation speed and is conducive to sludge dewatering.

(4) Anti-corrosion and anti-scale of circulating cooling system. The use of polyacrylamide can greatly reduce the amount of inorganic flocculant, so as to avoid the deposition of inorganic substances on the surface of the equipment, slow down the corrosion and scaling of the equipment.

2. Application in oil recovery

Polyacrylamide is a kind of multifunctional oil field chemical treatment agent, widely used in oil drilling, cementing, completion, workover, fracturing, acidification, water injection, water plugging profile control, tertiary oil recovery operation process, especially in the drilling, water plugging profile control and tertiary oil recovery field. Polyacrylamide aqueous solution has high viscosity, good thickening, flocculation and rheological regulation, and is used as an oil displacement agent and drilling mud regulator in petroleum exploitation. In the middle and later stage of oil exploitation, polymer flooding and asp flooding are mainly promoted in China to improve oil recovery. By injecting polyacrylamide aqueous solution, the oil-water velocity ratio was improved, and the crude oil content in the produced product was increased. The addition of polyacrylamide in tertiary oil recovery can increase oil displacement ability, avoid formation breakdown and improve oil bed recovery. China's petroleum industry is the largest user of polyacrylamide, the scientific and technological progress of polyacrylamide has promoted the development of China's petroleum industry, and the demand of the petroleum industry has accelerated the pace of scientific and technological innovation of polyacrylamide and the development of the industry.

3. Paper industry

Polyacrylamide is widely used in the field of papermaking as retention aid, filter aid, homogeneity agent to improve the quality of paper, slurry dehydration performance, fine fiber and filler retention, reduce raw material consumption and environmental pollution, as a dispersant, can improve the uniformity of paper. Polyacrylamide in the paper industry is mainly used in two aspects, one is to improve the retention rate of filler, pigment and so on to reduce the loss of raw materials and environmental pollution; The second is to improve the strength of the paper. Adding polyacrylamide into paper can improve the retention rate of fine fiber and filler particles on the net and accelerate the dehydration of paper. The mechanism of action of polyacrylamide is that the particles in the slurry are electrically neutralized or bridged so that flocculation can be retained on the press cloth. The formation of flocs can also make the water in the slurry easier to filter out, reduce the loss of fiber in white water, reduce environmental pollution, and help to improve the efficiency of filtration and precipitation equipment.

4. Medical materials

Polyacrylamide gel can be used as non-thrombin progranulator, surgical, contact lens raw material, microcapsule outer coating material, and used to manufacture high quality hemostatic tether, women's sanitary napkin and children's diapers. Polyacrylamide with particle sizes ranging from hundreds of microns to tens of microns can be used as chromatographic fillers (e.g. gel chromatographic column fillers) to effectively separate spherical proteins such as cytochrome. It can further desalinate and concentrate protein. Through Mannich reaction, l-proline or L-hydroxyproline was introduced into polyacrylamide side chain via methylene bridge, and then coordinated with copper ions to obtain chiral ligand resin, which can effectively split a series of DL amino acids. The chiral amino acids of polyvinylamine resin degraded by Hofmann are then complexed with copper ions, which can be used as the stationary phase of ligand exchange chromatography for the resolution of a series of amino acids, especially aromatic amino acids. Due to the strong hydrophilicity of the skeleton, the resolution time is greatly shortened.

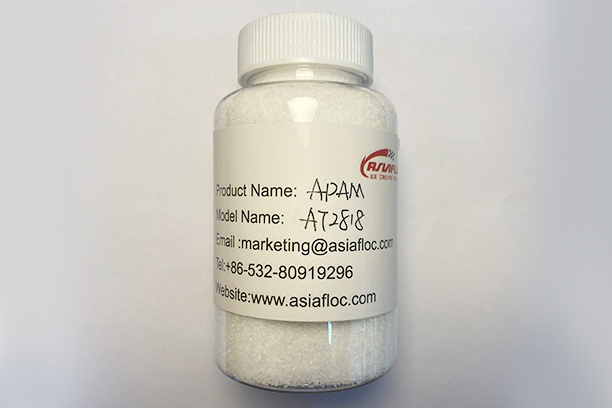

The picture

5. Other industries

Food industry, used for sugar cane sugar, sugar beet sugar production cane juice clarification and syrup phosphorus float extraction. Enzyme preparation fermented liquid flocculation clarifying industry, also used in feed protein recovery, stable quality, good performance, recovery of protein powder to chickens and raising the survival rate of weight gain, no adverse effects of egg production, synthetic resin coating, civil water plugging grouting materials, building materials industry, improve the quality of cement, construction adhesive, caulking repair and plugging agent, soil improvement, electroplating industry, printing and dyeing, etc.

551.jpg)