Anion non-ionic polyacrylamide pre-hydrolyzed emulsion was used as drilling fluid material during drilling. The primary effect is to increase the viscosity of the drilling fluid, to coat, to control, to reduce the filtration loss, to protect the wall, to smooth the bit, and to make the flocculating cuttings easier to slag out. Non-ionic polyacrylamide with temperature and salt resistance is used to drive oil in the third production of oil field. Profile control and plugging use non-ionic polyacrylamide to participate in cross-linking agent for gels.

The application of nonionic flocculant used in oilfield-Asiafloc

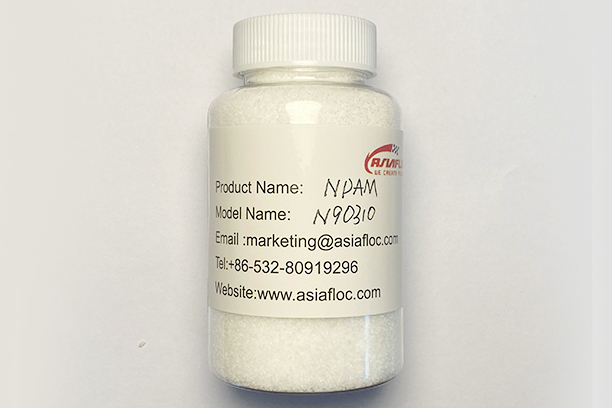

Color

- white granular

Application

- water treatment ,mineral processing,oilfield

Certificate

- ISO9001,ISO14001

Place of Origin

- China

The application of nonionic flocculant used in oilfield

Usually we use non-ionic polyacrylamide is for sewage, wastewater treatment. In fact, its role is much more than that, in the oil field and drilling can also play a great role. Non - ionic polyacrylamide can be called "100 industry additives" is not without reason. Yongkun will give you a detailed explanation:

Anion non-ionic polyacrylamide pre-hydrolyzed emulsion was used as drilling fluid material during drilling. The primary effect is to increase the viscosity of the drilling fluid, to coat, to control, to reduce the filtration loss, to protect the wall, to smooth the bit, and to make the flocculating cuttings easier to slag out. Non-ionic polyacrylamide with temperature and salt resistance is used to drive oil in the third production of oil field. Profile control and plugging use non-ionic polyacrylamide to participate in cross-linking agent for gels.

What is the effect of non-ionic polyacrylamide as a dispersant?

It is mainly used as paper dispersant and textile sizing agent. The primary effect of paper dispersant is to make the fiber and filler more evenly distributed on the paper, so that the paper is uniform smooth without holes. The primary effect of textile sizing agent is to make the slurry invade and roll onto the fabric, so that the fabric is smooth, thick and full, and stiff.

What is the effect of non-ionic polyacrylamide in shale gas fracturing?

It can be used as a drag reduction agent for fracturing, because to reach the field application conditions, the use of more quick-dissoluble non-ionic polyacrylamide emulsion and non-ionic polyacrylamide fine powder products, to decrease the rough fluid turbulence in the pipeline, reduce the effect of molecular movement resistance.

551.jpg)